| |

|

![]()

Where pencil leds work, as Carbon Arc electrodes, they burn out quickly. Carbon Arc became a commercial venture only after Manufacturing Techniques were developed.

Davy used for his first experiments rods of wood charcoal which had been heated and plunged into mercury to make them better conductors. Not until 1843 was it proposed by J. B. L. Foucault to employ pencils cut from the hard graphitic carbon deposited in the interior of gas retorts. In 1846 W. Greener and W. E. Staite patented a process for manufacturing carbons for this purpose, but only after the invention of the Gramme dynamo in 1870 any great demand arose for them. F. P. E. Carre in France in 1876 began to manufacture arc lamp carbons of high quality from coke, lampblack and syrup.

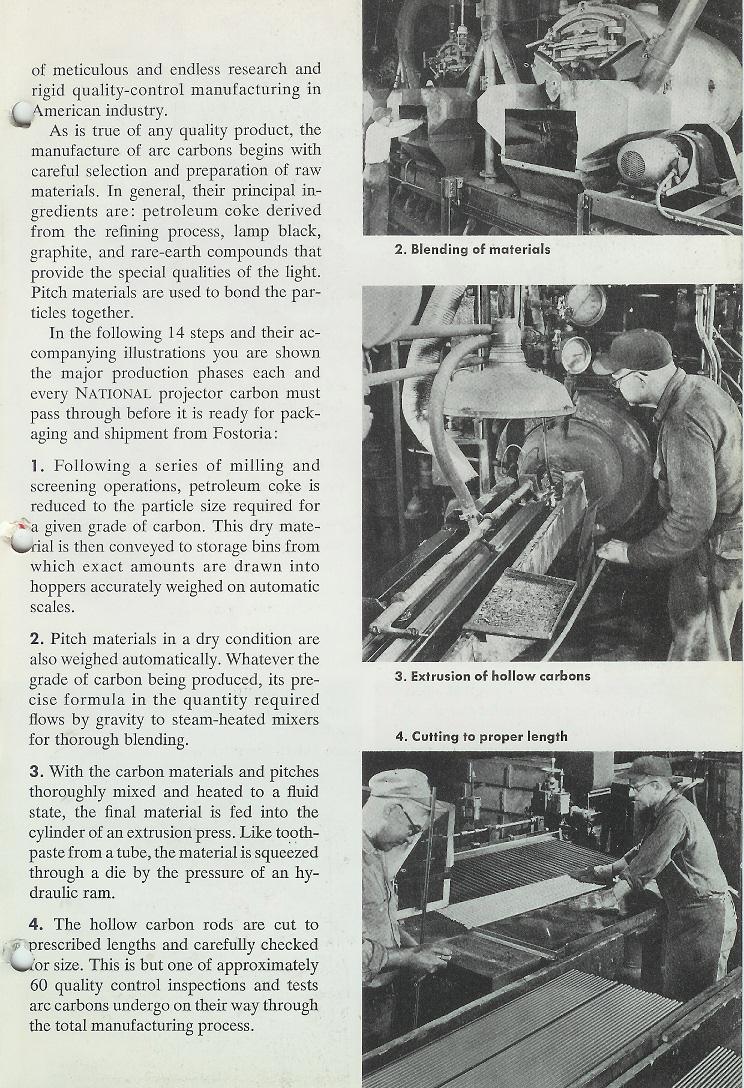

Manufacturing the rods is a complex process involving high heat, not something an Aftertime community could readily setup, as this description from the National Carbon Projector bulletin shows.

The following pages were scanned from a National Carbon Projector Bulletin from 1964 Published for Motion picture projectors, the process is the same for Searchlight carbons The bulletin will give you an idea of the costly process involved in making these carbons for searchlights